In the ever-evolving landscape of electronic components, the significance of choosing the right packaging solutions cannot be overstated. ESD bags, specially designed to safeguard sensitive electronics from electrostatic discharge, play a crucial role in maintaining product integrity and reliability. According to a report by the Electrostatic Discharge Association (ESDA), improper handling and inadequate packaging contribute to approximately $5 billion in damages to electronic products annually. This staggering figure underscores the importance of selecting high-quality ESD bags tailored to specific needs.

Dr. Emily Carter, a renowned expert in electrostatics and material science, emphasizes the necessity of finding the right protective solutions: "Investing in the appropriate ESD bags not only protects your electronic components but also ensures customer satisfaction and reduces long-term costs." With such profound insights, it becomes evident that thorough consideration must be given to factors such as material, thickness, and sealing methods when choosing ESD bags. In this article, we will explore the ultimate tips for selecting the best ESD bags for electronic components, empowering manufacturers and retailers to make informed decisions that enhance their operations and quality control processes.

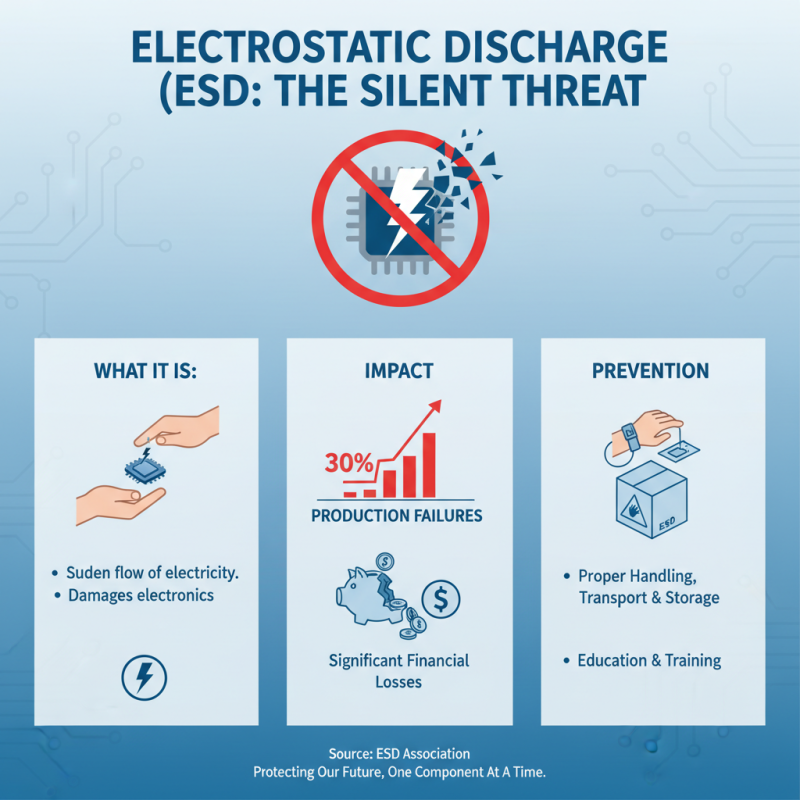

Electrostatic Discharge (ESD) poses a significant threat to electronic components, leading to failures that can result in substantial financial losses for manufacturers. According to the ESD Association, ESD damage accounts for around 30% of all failures in electronic devices during production, making education and proper handling essential. Understanding the nature and implications of ESD is crucial for safeguarding sensitive electronics throughout their lifecycle. The prevention of ESD is imperative not only in manufacturing but also during transportation and storage, where improper handling can compromise the integrity of components.

When selecting ESD bags, it is vital to consider the specific requirements of the components being stored or transported. Tips for choosing ESD bags include assessing the material's conductivity: bags with a surface resistivity ranging from 10^6 to 10^9 ohms per square provide adequate protection for various electronic parts. Additionally, clarity is important; transparent ESD bags allow for easy inspection without removing the components. Furthermore, ensure that the bags meet industry standards such as ASTM D257 and are appropriately labeled to signify ESD protection.

Another key aspect to consider is the thickness of the ESD bag, which should be sufficient to prevent punctures while still allowing flexibility. Thicker bags typically offer better protection, particularly in environments susceptible to physical damage. Investing in the right ESD bags can significantly reduce the risk of damage during handling and storage, ultimately preserving the safety and functionality of electronic components.

When it comes to selecting the best electrostatic discharge (ESD) bags for electronic components, understanding the different types of materials available is crucial. Commonly used materials for ESD bags include polyethylene, polypropylene, and static shielding materials. Polyethylene bags are lightweight and cost-effective, making them a popular choice for general purpose usage. They provide basic protection against dust and moisture, but are less effective against static electricity. On the other hand, polypropylene bags offer better durability and clarity, which is ideal for applications where visibility of the contents is important, while still providing essential ESD protection.

Static shielding bags, often made from metalized materials, provide the highest level of protection against electrostatic discharge. These bags create a Faraday cage effect, effectively isolating sensitive electronics from environmental ESD. They are particularly recommended for high-value or sensitive components that require maximum safeguarding. Understanding the specific application and environment in which the ESD bags will be used is essential for making an informed choice, as this will ultimately determine the most suitable material and type for your electronic components.

When selecting ESD (Electrostatic Discharge) bags for electronic components, it is essential to consider several key features that ensure optimal protection. First and foremost, the material of the bag plays a critical role in its effectiveness. Look for bags made of dissipative or conductive materials that are specifically designed to prevent static buildup. This helps protect sensitive electronic parts from damage caused by static electricity during handling and transport.

Another important feature to examine is the bag's thickness and durability. Thicker bags generally provide a higher level of protection against physical stress, moisture, and contaminants that could compromise the integrity of electronic components. It is also wise to consider the closure mechanism of the bag; resealable options offer flexibility for accessing components while maintaining ESD protection. Additionally, bags that include clear windows allow for easy identification of contents without needing to open the bag, further enhancing protection against inadvertent static discharge.

When using ESD bags for electronic components, proper handling practices are crucial to ensure maximum protection against electrostatic discharge. First and foremost, it is essential to always ground yourself before handling ESD-sensitive items. This can be done by using an ESD wrist strap or touch point to dissipate any static charge. Additionally, ensure that the workspace is static-free, with the use of ESD mats and avoiding polyester or wool clothing that can generate static electricity.

The correct usage of ESD bags also involves knowing how to store and transport electronic components properly. Always seal ESD bags securely after placing the components inside to prevent any movement that could generate static. When transporting items, avoid stacking heavy objects on top of ESD bags to protect them from crushing. Moreover, store ESD bags in a cool, dry environment away from direct sunlight and sources of heat, as extreme temperatures can compromise the integrity of the bags and the components within. By following these guidelines, you can significantly reduce the risk of electrostatic damage to sensitive electronic parts.

| Feature | Description | Best Practice |

|---|---|---|

| Material | ESD bags are typically made from polyethylene or metallized materials to prevent static electricity. | Always choose a bag made from high-quality materials for better protection. |

| Thickness | Thickness can range from 2 - 6 mil; thicker bags provide more protection. | Select the appropriate thickness based on the level of protection required. |

| Size | Bags come in various sizes to accommodate different components. | Choose a size that fits the components snugly without excess space. |

| Closure Type | Closure styles include self-sealing, ziplock, and tape closure. | Use a closure type that is easy to use and provides a secure seal. |

| Labeling | Bags should be clearly labeled with appropriate warnings and handling instructions. | Ensure all staff are aware of ESD protocols and bag handling information. |

When selecting ESD bags for electronic components, understanding the proper maintenance and storage practices is crucial for ensuring their longevity and effectiveness. ESD bags, designed to protect sensitive electronic devices from electrostatic discharge, require specific care to maintain their protective properties. Studies indicate that improper handling or storage can significantly reduce their lifespan; for instance, temperature extremes can cause degradation, while exposure to contaminants may reduce the bags' effectiveness in dissipating static electricity.

To extend the usability of ESD bags, it is essential to store them in a cool, dry environment away from direct sunlight and sources of heat. Data from the Institute of Environmental Sciences and Technology (IEST) suggests that a controlled environment typically enhances the durability of ESD packaging materials. Additionally, it is recommended to frequently inspect the bags for any signs of wear or damage, as even minor imperfections can compromise their protective capabilities. Regular training for staff handling ESD bags can also improve their proper usage, as educated personnel are less likely to inadvertently cause damage through improper handling practices. By implementing these maintenance strategies, organizations can better safeguard their electronic components and optimize the lifespan of ESD bags.

This chart illustrates the usage of various types of ESD bags suitable for electronic component storage and maintenance. The data highlights the popularity of each type based on user preferences.

Interested in working with our team? Reach out to our team for a no-strings-attached consultation.

1 (833) PPC-FLEX

1111 Busch Pkwy

Buffalo Grove, IL 60089, USA